Sheet metal design student guide enables you to use your introductory modeling skills to create sheet metal models including wall bends notches and form features.

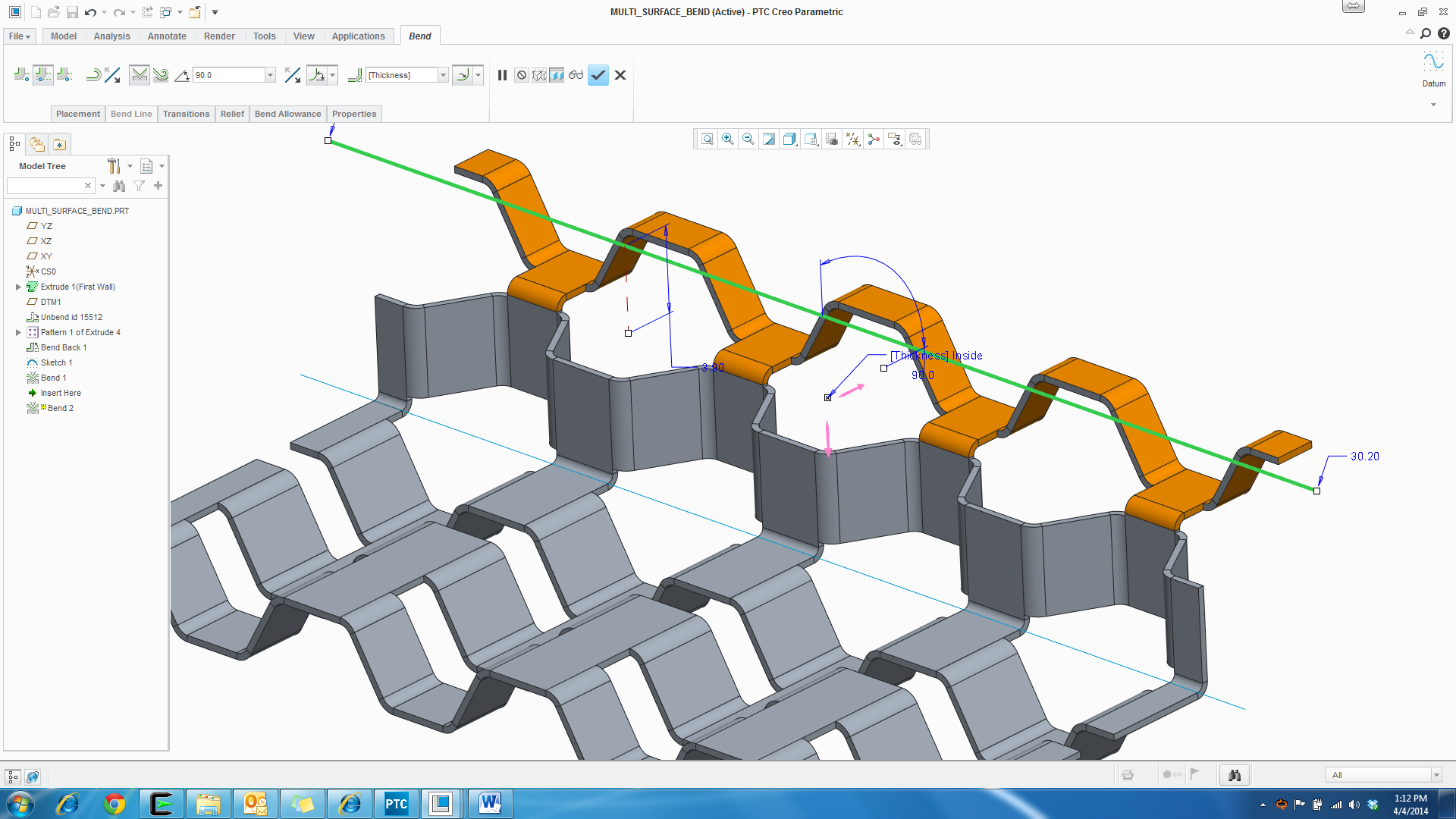

Creo 3 0 sheet metal bending.

Creo parametric 3 0.

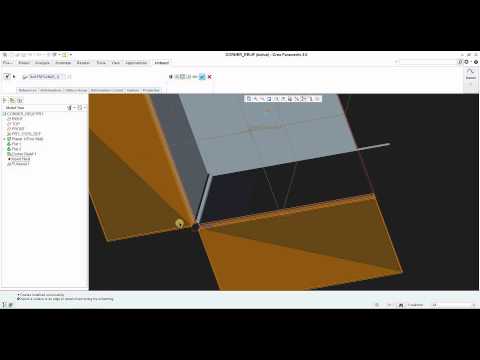

One way to do it of course it is to convert it as a surface copy surfaces convert to sheet metal and use offset tool.

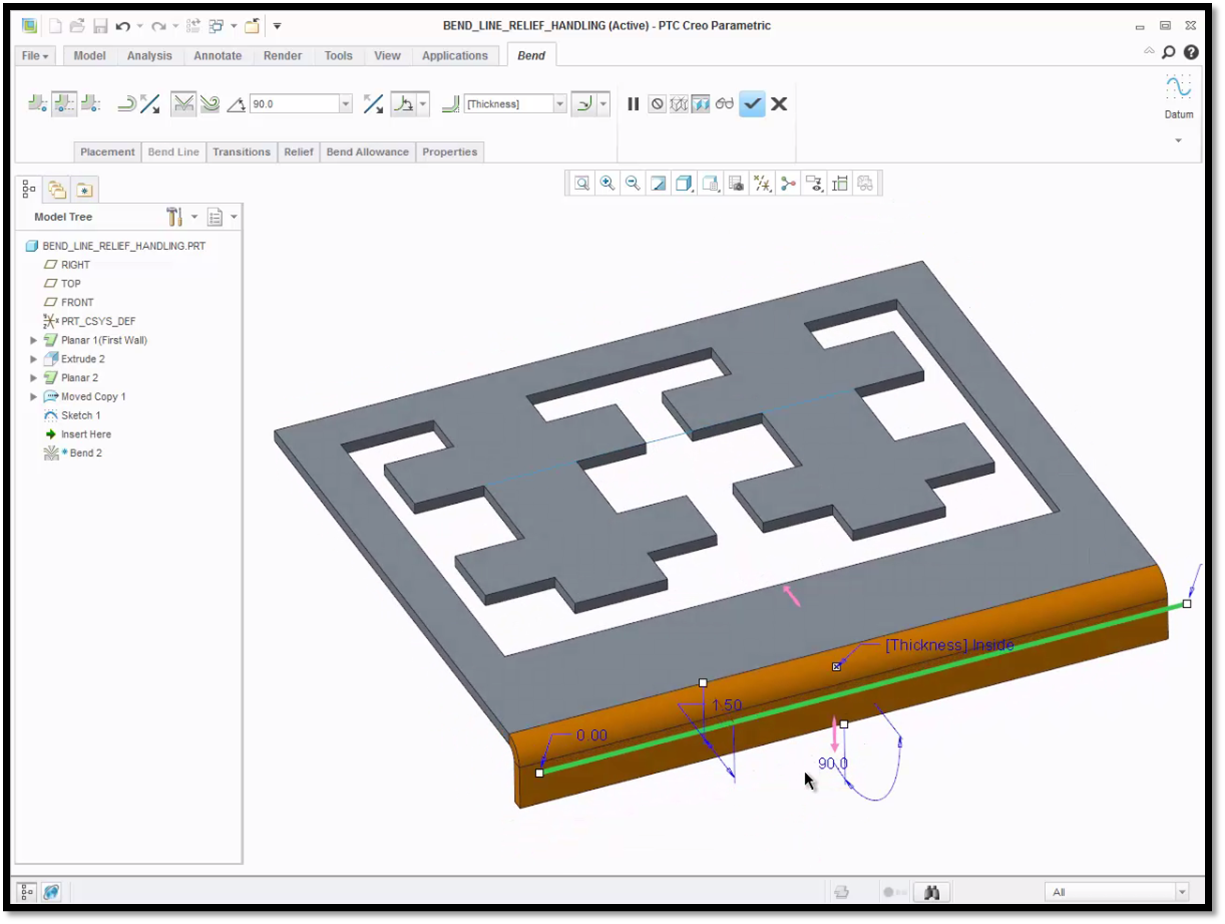

What is the method to create sheet metal bend that has a flat area as shown since bend line in sketch must be one entity.

Start by selecting the bend surface.

The only problem is that creo takes bending factors into account.

Now that you have a sheet metal part just go to the edit bend command.

But then the inner surface between the roller features leaves out.

I am new to creo and ive been creating flat patterns using a family table.

When i have the flat sheet metal i can sketch and extrude my pattern.

I thought they added something for this in creo 3 0.

The bend notes do not show up even though they are turned on in options under sheet metal bend notes display settings show bend notes.

In the creation.

I thought the easiest way would be to revolve the cylinder in sheet metal and then flatten unbend.

See convert a solid part into a sheet metal part for details.

Creo does not recognize the part when trying to convert it to sheet metal as picking driving surface.

This is a simplified version so i can t use forms or punches.

The creo parametric 3 0.

Click edit bend in the mini toolbar.

I need to make a cylinder with a laser cut pattern.

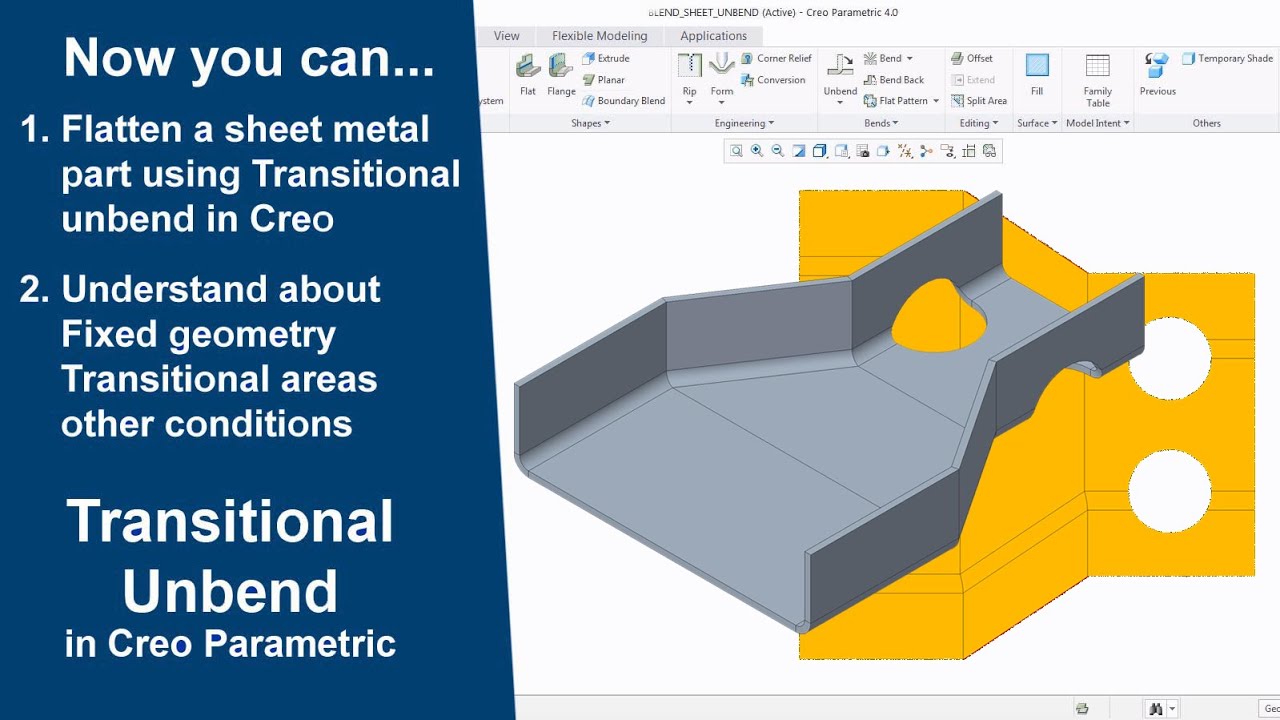

In this tutorial we will learn about the basic techniques related to sheet metal functionality of creo parametric by modelling a cover.

Creo creoparametric creotutorial tutorial 4kside vpalffy vladimirp.

For this example to the part has designed roller forming.

Just convert the imported 3d model into a creo sheet metal part by defining a driving surface and you re ready to go.

Short video tutorial of sheetmetal extrude feature sheetmetal from scratch.

If i had to i would add the tongue after the bend feature.