Optimized crankcase ventilation systems and the addition of a vacuum pump can swing positive crankcase pressures to zero atmospheric or even negative values vacuum.

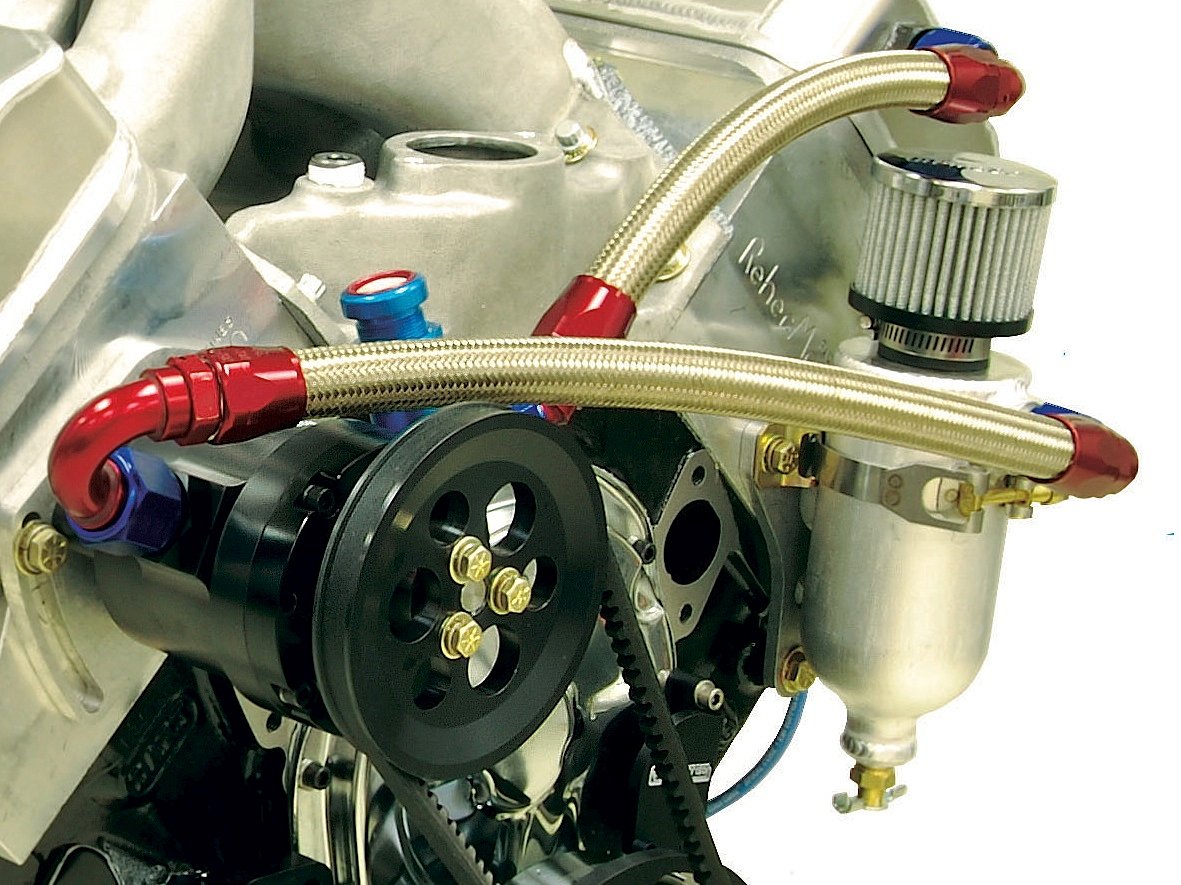

Crankcase vacuum pump system.

The gz motorsports racing vacuum pump are based on a brand new redesigned oem style air pump but are modified for use in an oily environment using parts designed specifically for that purpose.

At nrc it costs less than 100 for that extra stage.

This is done using a vacuum pump.

For most modest horsepower street engines however a vacuum pump.

The extreme solution to prevent all of this is to install a vacuum pump that continuously draws the pressure out of the crankcase.

The vacuum pump is an engine driven accessory that ensures that there s always plenty of vacuum capacity.

The pump can be either electric or mechanically driven but for an ideal solution should be connected to both the block and the valve cover to pull vacuum from both areas efficiently.

If you run a dry sump system with a three stage pump one pressure stage two scavenge stages in most cases you cannot achieve a sufficient level 8 hg of crankcase vacuum to achieve that power gain.

Upgrading to a high lift cam can reduce the available vacuum so you may need to upgrade your vacuum pump as well.

The net difference between the air being sucked out by the pump and the air generated by the engine with blow by yields the effective vacuum.

Belt or electric vacuum pump.

Crankcase pressure is evacuated via the valve cover and pumped to an external tank which vents the pressure and retains excess oil for periodic draining.

The extra cost of a four stage pump will net you around 15 hp in most cases.

This blow by airflow creates a positive pressure in the crankcase the vacuum pump sucks air out of the crankcase with its negative airflow.

Vehicles use the vacuum generated by the engine to operate the power brake booster and other pneumatic systems.

Actually an oem pump is a very reliable pump designed for many years of use because there s thousands of hours in gm and ford engineering in them.

Another option is to evacuate the crankcase and valve cover by pulling a negative pressure on it.